How To Choose The Right VFD Drive For Your Motor And Application?

Have you ever wondered how to choose the right VFD drive for your motor and application? Well, it's actually pretty easy. In this blog post, I'll show you how to do that using some basic equations that are easy to use and understand. Let's get started!

Gain a better understanding of the VFD drive market

VFD drives are used to control electric motors. They can be used in a variety of applications, ranging from HVAC systems to robotics and automation. VFDs can also come in a variety of sizes and configurations, depending on your specific needs.

In addition to these factors, you'll want to consider power output when choosing Perfect VFD Drives for your application. When it comes down to it, there are two main types: AC (alternating current) and DC (direct current). AC motors tend to have higher torque than DC ones but require more maintenance due to their brushes; meanwhile DC motors offer lower starting torque but don't require any maintenance over time because there aren't any moving parts inside them!

Know the types of power that is needed for your application

Before you can determine the right motor, you need to know what type of power is needed for your application. The first thing to consider when selecting a VFD drive is whether it will be used with AC or DC power.

- AC (alternating current): This is what comes out of most wall sockets and can be converted into DC by an inverter.

- DC (direct current): Direct current flows in one direction only, like when batteries are charged by solar panels or wind turbines generate electricity through motion blades.

If you need the motor to run on AC power, then you’ll need an AC drive. This will allow you to control the speed and direction of the motor using a variable frequency signal that comes from a controller or PLC (programmable logic controller).

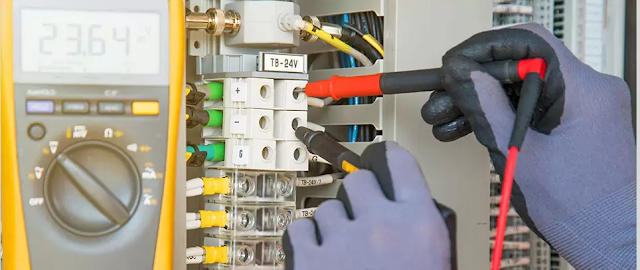

Consider the mounting configuration and installation requirements

Mounting configuration and installation requirements are crucial to a Successful VFD drive. The mounting type, location, installation requirements, and environment must be considered before choosing a motor.

- Mounting type: The three most common ways of mounting VFDs are through an enclosure or housing (enclosed), surface mount (non-enclosed) and integral mounting with the gearbox or motor itself (integral).

- Installation location: This depends on where you want your control panel located relative to where power will be fed into it--or whether this will be done remotely via fiber optic cable or wireless connection such as Bluetooth Low Energy (BLE).

- Installation environment: You also need to consider whether your application requires protection from dust or moisture because some types aren't suitable for use in wet environments due to their low IP rating rating

You also need to consider whether your application requires protection from dust or moisture because some types aren't suitable for use in wet environments due to their low IP rating.

If you're looking to upgrade or replace your Vfd Drives , we hope this guide has helped you understand the most important factors to consider when making that decision.

Comments

Post a Comment