What Is The Purpose Behind Variable Speed Drives?

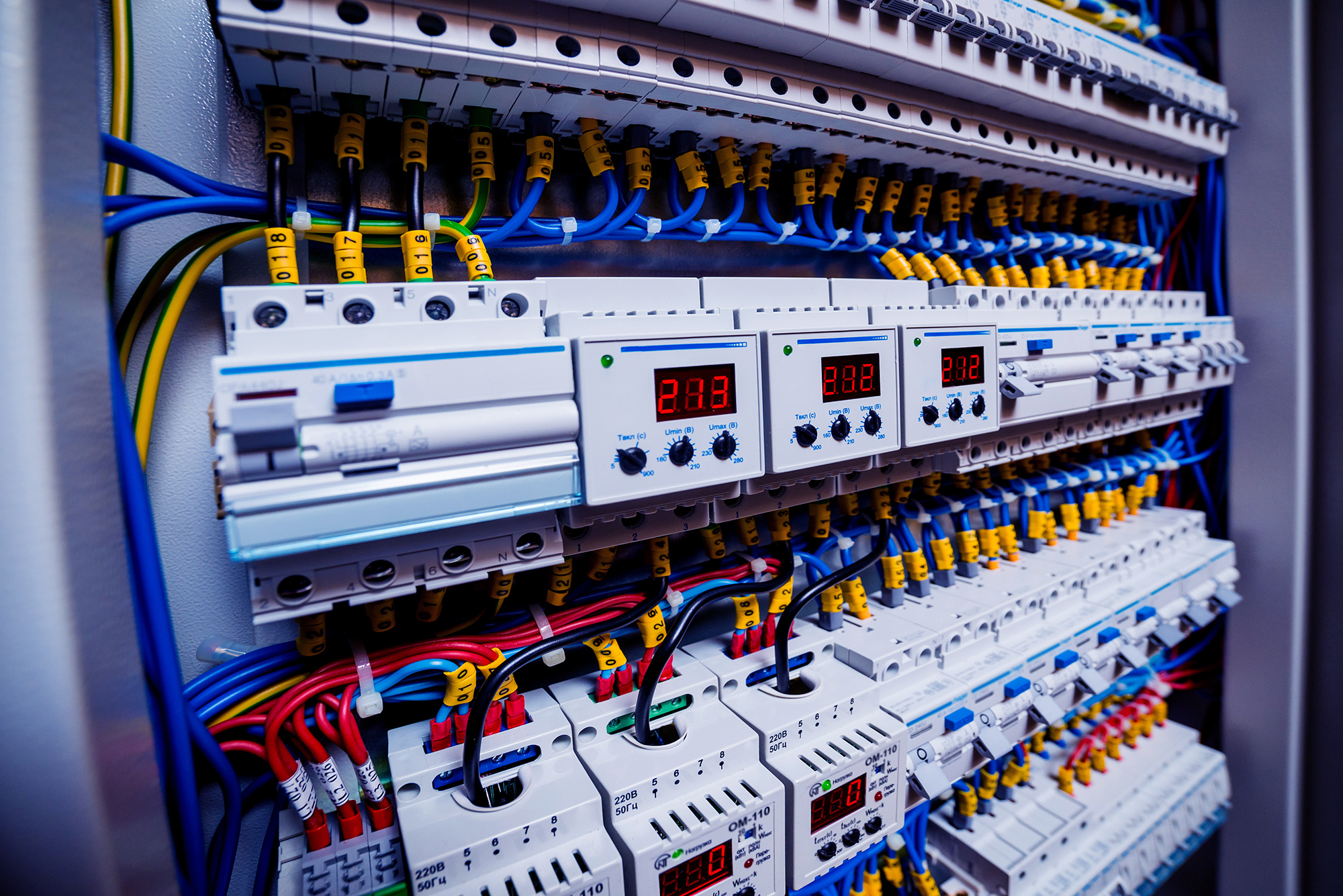

Variable speed drives (VSDs) have become a staple in the world of industrial manufacturing. While they are often found in factories, they can also be used in homes and offices to help control energy usage and improve efficiency.

According to a recent report , Vsds Electrical accounted for roughly 20% of all industrial motors worldwide by 2011—a statistic that shows just how widely VSDs are used across industries.

Improved control and precision

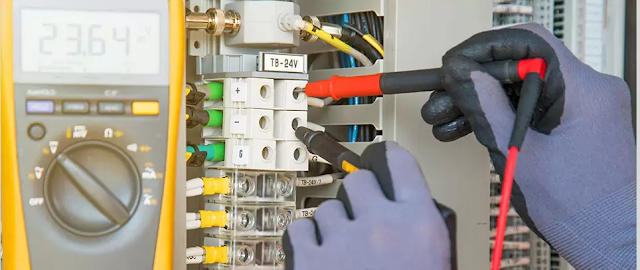

The benefits of Vsds Electrical go beyond energy savings. The ability to control and regulate the speed at which a motor operates makes it possible to better control your machine’s performance, resulting in smoother acceleration and deceleration.

When you reduce these movements, you also reduce wear on equipment components like belts, bearings and motors themselves. This leads to increased safety by reducing the risk of fire or explosion due to overheating due to excessive heat build-up.

In addition to improving performance and reducing wear-and-tear on equipment, VSDs can help save money by increasing efficiency while consuming less power than fixed-speed motors.

VSDs can allow for easier, smoother operation, control over acceleration

VSDs have many advantages over traditional speed control systems. They allow for easier, smoother operation and control over acceleration. VSDs are also a versatile solution in terms of end use and application for your machine.

VSDs provide a way to control the output speed of an AC motor by varying its field current as a function of load torque or other external signals (e.g., position).

This reduces stress on both the motor and power supply compared with constant-speed operation at full rated voltage, where torque may be excessive if there is insufficient cooling or lubrication oil flow rate is inadequate because of unbalanced loads or other problems associated with high speeds such as back emf voltage spikes caused by rapid acceleration which can result in overheating if not properly cooled (e.g., fan failure).

Eliminates the large, abrupt surges of energy

Using a Vsds Electrical can eliminate the large, abrupt surges of energy that many electric motors experience. This feature is important because it reduces the amount of energy wasted and reduces wear and tear on equipment.

As a result, less maintenance is required over time. In addition, because the equipment's life will be extended, you'll experience greater efficiency in your business.

Variable speed drives can also be used to control the speed of a motor. This is important because it allows you to precisely match the speed of your equipment to the application at hand. For example, if you're running a machine that requires consistent torque.

Conclusion

In summary, Vsd Electrical allow you to automate the speed of machinery. This gives you more control over your operation and makes it much easier to ensure smooth operation. By reducing the amount of energy wasted on sudden surges, they can also help improve efficiency.

Comments

Post a Comment