Variable Speed Motor Drive: All Facts You Need To Be Aware Of

A variable speed motor drive is a type of motor that is used to control the speed of a fan, pump or compressor based on an input signal. This can be achieved by using a simple pulley system or by using an electronic feedback loop.

When can you use such a type of motor?

Motor drives are used in many ways, depending on how you want to use them. For example, if you need a motor to run at different speeds and/or you need to control the speed of a motor, then it is more efficient and cost effective to use a variable speed drive.

This type of motor drive can also be used for controlling the direction of your motors. If you want your motors or other equipment to turn off automatically after being left idle for some time period (e.g., when doing assembly line work), then this kind of automatic shutoff can be accomplished using an intelligent motor controller (IMC).

How does a variable speed motor work?

You might be wondering how a variable speed motor works. To understand this, it helps to know what a variable speed motor drive is. A variable speed motor drive is the part of an electrical system that receives power from a controller and then regulates the amount of voltage to the phase windings of an induction motor.

The phase windings are connected to slip rings which allow them to rotate freely on their shafts and so provide power to all three phases at once in order for them all to work together as one.

The types of motors may vary in design, but they all share this function: they are able to take incoming electricity and turn it into rotational motion by using magnetic fields generated within coils (or windings) inside each motor housing.

Now let's talk about how a variable speed motor works! There are two main components that make up any type of induction machine: stator laminations (which hold permanent magnets), rotor laminations (which collect iron cores with copper wire wrapped around them).

What are the main components of a variable speed motor drive?

The main components of a variable speed motor drive are:

- Power supply - connects to the energy source and converts it into electrical power. The most commonly used power supplies are the transformer, capacitor and inverter.

- Motor - drives the process by converting electrical energy into mechanical motion. The motors include induction motors, DC motors and servo motors that rotate at constant speeds despite load variations or disturbances.

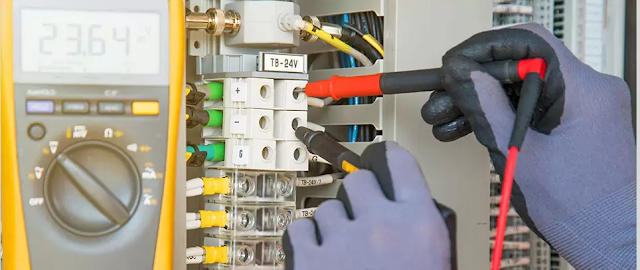

- Controller - controls the functioning of a variable speed drive by sensing its operation parameters like voltage or current levels, temperature etc., which is fed back to control circuit through feedback sensor. There are two types of controllers available in VSDs such as analog controller and digital controller based VSDs.

Conclusion

There are many different types of Variable Speed Motor Drive, but the variable speed is probably the most common one. Because it can adjust its speed according to the needs of your machinery, it’s perfect for industrial applications where there are many different requirements from one day to another.

Comments

Post a Comment